| RESEARCH AND DEVELOPMENT |

Research

and Development

is an innate tradition at Sefco.

Self-supported R&D programs are currently conducted to improve existing technology, as well as research and develop new concept: Field-operation analyses are achieved in collaboration with customers. The results of the analyses enable Sefco to create evt more efficient products, to justify the acceptability of technical improvements and demonstrate the advantage of new designs. In the end, our R&D activities provide the following: leadership in making available unexcelled standards and new equipment products of exceptional quality and reliability appreciable return on product investment |

|

| ENGINEERING |

Engineering where a team of specialists convert elaborate ideas and developments into practical realizations where projects are carefully conducted and successfully completed ...where customer inquiries are thoroughly analysed and answered with expertise.

Sefco's engineers have profound knowledge and extensive experience with respect to cryogenic pumping systems and associated applications.

They are alert to customer requests and will provide the most efficient and economical design.

They monitor the manufacturing of a product beginning with project planning and through data processing - documentation - design - production - quality control, ending with the acceptance testing and clearing of the product. |

|

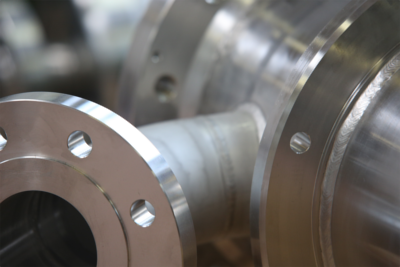

| MANUFACTURING |

sefco is persistent in its search for manufacturing excellence. Quality workmanship according to the finest construction practices,

material processing through advanced machining methodes, inhouse precision assembling, rigid inspection and quality control, are the rule at Sefco.

This manufacturing practice within modern facilities has created the ever increasing demand for a sefco Cryogenic centrifugal pump, famous for its high quality-standard. |

|

| TEST-FACILITIES |

Sefco has two of the finest cryogenic and hydrodynamic test facilities.

They are fully equipped for large scale R&D investigations, as well as endurance and acceptance tests.

The cryogenic test-facility disposes of a liquid nitrogen capacity of 60'000 liters.

With such testing capability, almost any investigation of actual or simulated product operation can be completed.

Prior to delivery, each pump passes an acceptance test under cryogenic conditions. This precedes: secures product readiness for safe and reliable operation at its required performance level. |

|

| QUALITY ASSURANCE |

Quality Assurance

is the engrained norm at Sefco.

We guarantee quality assurance through our devoted professionals, integrated safety regulations and standards, rigid control and inspection at all phases of product evolution.

The QA-responsible has sufficient freedom from line organizations to ensure deletion and correction of conditions adverse to quality. |

|